Abstract: GD300L is special elevator drive developed for all type of elevator like home lifts, passenger and goods lifts etc. This paper gives the detailed solution installation and commissioning details for VVVF drive. Engineering practices, market survey and feedback show that GD300L has good control performance and stability compare to other brands.

Keywords: INVT GD300L, Johnson controller and Geared Machine, Elevator AC drive.

I.Introduction

GOODRIVE300L series inverters are the new-generation inverters developed based on INVT’s newest control platform. As using TI 28-series DSP and advanced vector control technology, Goodrive300L series inverter improved great achievements in security and reliability, control performance, use functions and basic performance.

Basic performance:

Ability to drive asynchronous (Geared) and synchronous (Gearless) motors

Support open loop control mode without encoder and closed loop control mode with encoder.

Static motor auto tuning for the initial pole angle so that not required to de-roping of the motor

Support multiple type of encoder: Support incremental, sine-cosine, absolute encoders.

Energy saving running mode: Support the use of RBU, implementing energy saving running.

Optional LCD keypad.

II.Configuration of GD300L elevator

Installation of GD300L on lift has below detail:

Tab 1 Lift information

| Lift speed | 1.0 m/s |

| Capacity | 6 persons, 408KG |

| Floor | 11 floors |

| Power supply | 3phase 415V |

| Motor type | Asynchronous motor |

| Rated power of motor | 7.5 kW |

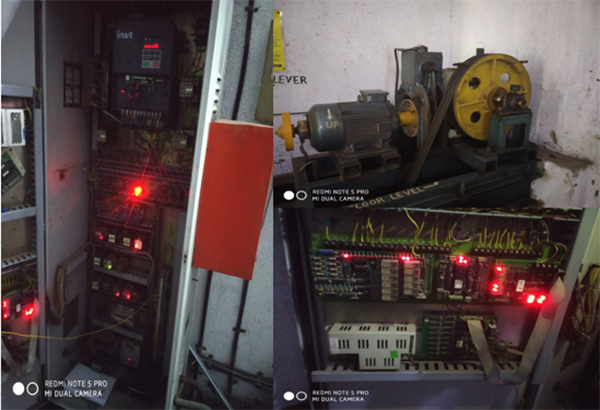

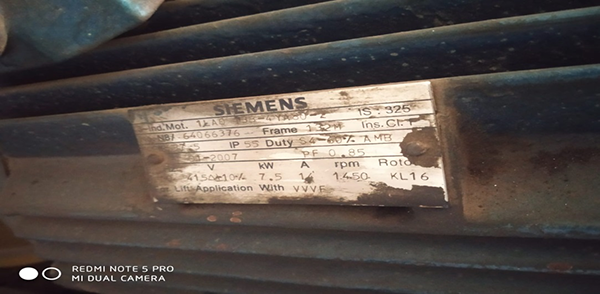

Fig INVT GD300L Control Panel and motor with nameplate

1.GD300L electrical configuration

According to the lift configuration and the demanding functions, we provide the electrical solution as follow. Considering higher ambient temperature, one grade higher of machine rating is selected.

Tab 2 Configuration list

| Item | Model | Qty |

| GD300L Inverter | GD300L-011G-4 | 1 |

| Geared Motor | SIEMENS | 1 |

| Brake resistor | 40 OHM 4000W | 1 |

2.GD300L parameter setting

Basic parameters setting are as follow.

| GEARED MOTOR WITH GD300L (OPEN LOOP) | ||

| FUNCTION CODE | NAME | SET VALUE |

| P00.00 | SPEED CONTROL MODE | 1 |

| P00.01 | RUN COMMAND CHANEL | 1 |

| P00.02 | LIFT RATED SPEED | DEPENDS ON MOTOR NAME PLATE |

| MOTOR PARAMETER | ||

| P02.00 | MOTOR TYPE | 0 |

| P02.01 | KW (POWER) | 7.5KW |

| P02.02 | HZ (FREQUENCY) | 50HZ |

| P02.03 | RPM | 1450 |

| P02.04 | VOLTAGE (V) | 415V |

| P02.05 | CURRENT (AMP) | 14 |

| P11.08 | MOTOR OVERLOAD DRIVE TRIP | “010” |

| INPUT TERMINAL | ||

| P05.01 | FORWARD (S1) | 1 |

| P05.02 | REVERSE (S2) | 2 |

| P05.03 | SLOW SPEED (S3) | 8 |

| P05.04 | HIGH SPEED (S4) | 9 |

| P05.05 | INSPECTION COMMAND (S5) | 10 |

| P05.06 | BASEBLOCK (S6) | 25 |

| P05.07 | ARD (S7) | 4 |

| P05.16 | TERMINAL PROTECTION | 1 |

| OUTPUT TERMINAL | ||

| P06.05 | BRAKE (R02A) | 7 |

| P06.06 | MOTOR (R03A | 8 |

| SPEED PARAMETER | ||

| P09.01 | SLOW SPEED | 0.085 M/S |

| P09.03 | HIGH SPEED | 0.800 M/S |

| P09.04 | MAINTANCE SPEED | 0.300 M/S |

| TUNNING PROCESS | ||

| STEP-1 | P00.01=0 | |

| STEP-2 | P00.09=2 | |

| STEP-3 | MAKE SURE MOTOR CONTACTOR IDS “ON” AND DISPLAY IS SHOWING “TUN E” | IF MOTOR CONTACTOR IS NOT “ON” THEN PRESS IT EXTERNALLY WITH TESTER OR SCREEWDRIVER |

| STEP-4 | THEN PRESS GREEN COLOUR (RUN) BUTTON OF DRIVE | |

| STEP-5 | DISPLAY WILL SHOW RUN-1…RUN-2…RUN-3…AND THEN “END” AND MOTOR TUNNING WILL SUCCEED. IT WILL TAKE 120 SEC. | |

| STEP-6 | MAKE P00.01=1 AND TRY TO RUN THE MOTOR WITH UP OR DOWN COMMAND. | |

3.Connection Details

| DRIVE TERMINAL | CONTROLLER SIGNAL | INFORMATION |

| S1 | 18 | FWD |

| S2 | 19 | REV |

| S3 | 21 | SLOW SPEED |

| S4 | 22 | HIGH SPEED |

| S5 | 23 | MAINTAINCE SPEED |

| S6 | 16 | BASE BLOCK |

| “+24V” | 14 | COM |

| (IN DRIVE SHORT PW AND COM) | ||

| R02A | 10 | BRAKE RELAY |

| R02C | 8 | COM |

| R03A | 11 | MOTOR CONTACTOR |

| R03C | 8 | COM |

| # IN CONTROL CARD SS WIRE (TRAVELLING CONNECTOR STRIP) SHORT TO SEEK SIGNAL (CONTROL CARD) | ||

| # REMOVE SHORT SEEK SIGNAL AND RUN SIGNAL FROM CONTRL CARD | ||

III.Conclusion

After installation of the gd300l drive in three different type of elevator application as for

1. Gearless Motor (Close loop with encoder)

2. Geared Motor (Close loop with encoder)

3. Geared Motor (Open loop without encoder)

It is concluded that the gd300l drive gives very nice performance with easy debugging.